So this fall I've been upgrading the stereo system that came in our '15 LSV. It came with Kicker amp that is driving 6 cabin speakers and a 10" Kicker sub under the helm. I added an Exile 15.4 amp and a pair of XM9's to the tower. I also added a ZLD while I was doing the other stuff. That all went pretty smoothly other than getting the speaker wire through the tower. That was a PITA. Thanks to Brian at Exile for hooking me up with the equipment and getting me the deal on the ZLD even though I was a little early and for taking the time to help me and answer all my noob questions.

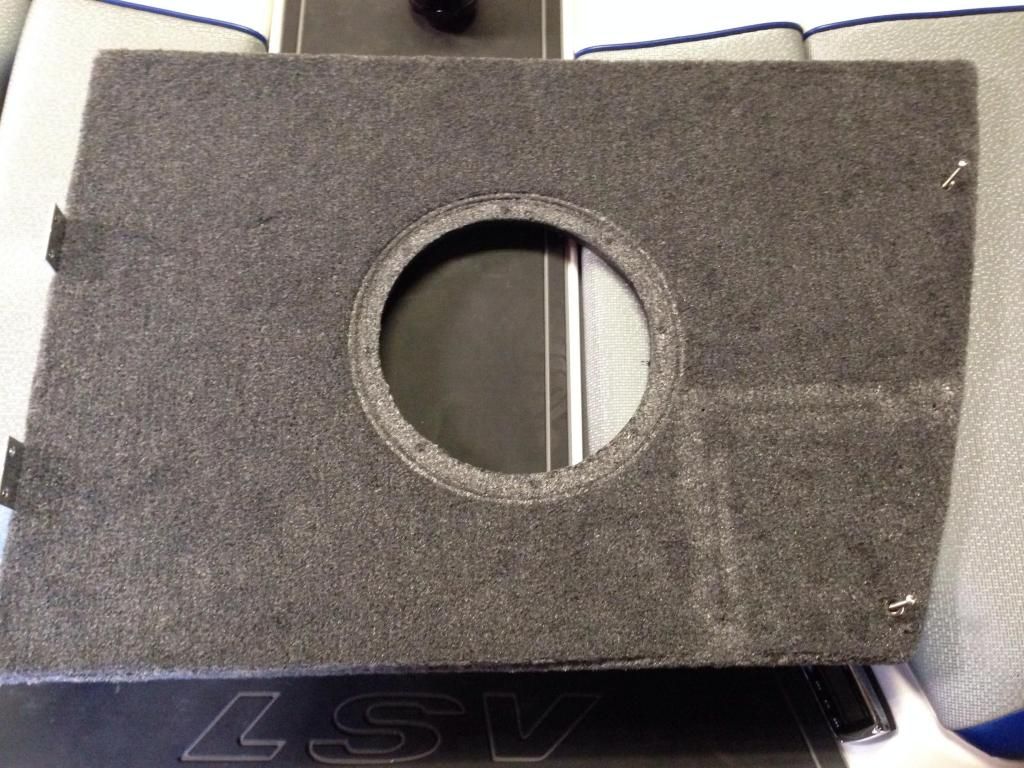

After getting everything installed and working with the amps I was able to isolate the sub and discovered just how bad it sounds. I would describe the sound as a buzz, not a buzz like something was wrong, just a bad sound. I adjusted the Kicker amp and was able to make it sound some better but still not good. The amp is just mounted on the facade under the helm. It's not in an enclosure and the area into the bow seat certainly isn't sealed . The facade doesn't go all the way to the top.

So I have decided that I'm going to enclose the sub. I have read several of the threads on here about doing this and had read about the infamous hump. I was leery of what I would find when I pulled it out. I was pleasantly surprised to find that there is no hump.

There is only about a 1/2" lip there from the carpet to the fiberglass. And it looks like the hole that the ballast hose passes through is far enough back to not create any problems. The facade that the sub is mounted to is a piece of 3/4" HDPE.

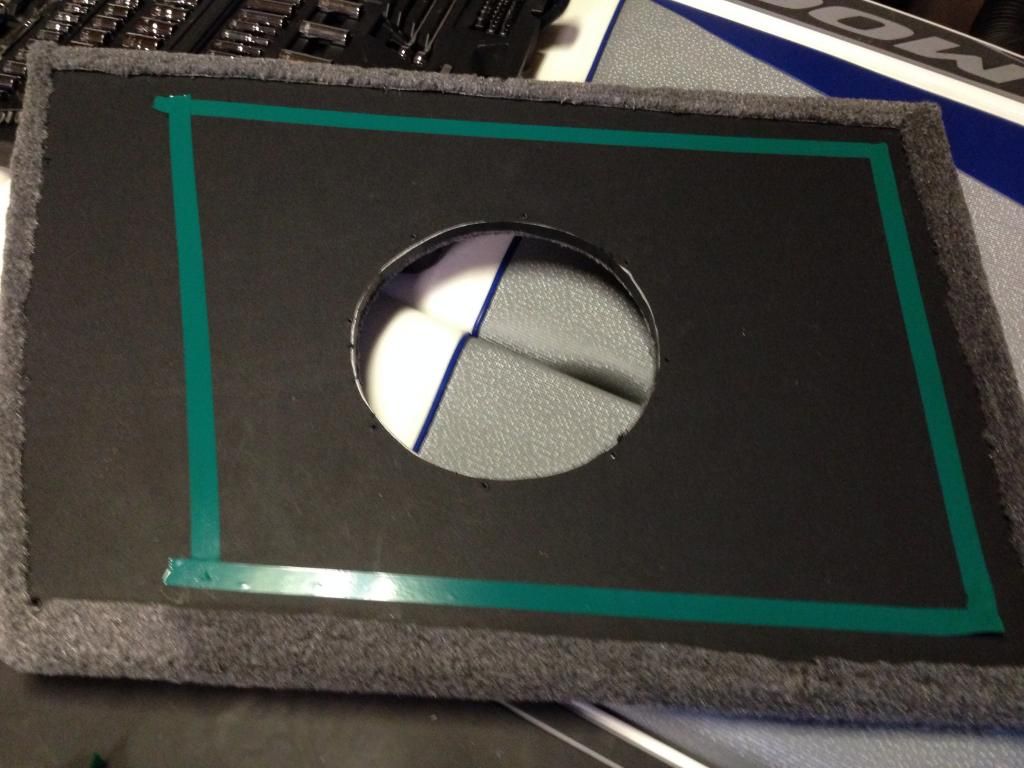

I think I can build an enclosure that will be 19.5"x16"x7" (inside dimensions) as shown by the tape and not have any issues with anything behind the facade and not have to move it forward either.

We use HDPE at my business and I'm thinking I'll just use that to make the rest of the enclosure and just attach it to the existing facade. Is there any reason that I wouldn't want to do that? The sub measures 5" from the facade, is 7" enough depth? Also, the manual for the sub says I should have at least 1 cubic ft for the enclosure. This is bigger than that but I wasn't sure how much to subtract for the space the sub takes up?